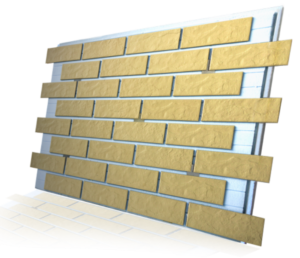

The thermal panel for the facade is a complex, monolithic structure. It consists of an insulation board (polyurethane foam (XPS), expanded polystyrene (PSB-S, EPS, PPS).

The outer finishing layer can be represented by different materials. You also need glue for a single connection between the insulation layer and the protective and decorative coating.

The process of gluing two materials occurs by pressing the tile into the insulation panel using a one-component polyurethane glue, which joins the structure of both materials along the entire thickness, creating a monolithic and durable structure – ceramic decorative + insulation = thermal panel.An adhesive mixture cannot provide a more reliable connection of two materials without the use of an additional pressure load with a penetrating effect on the structure of the materials to be glued.

Our company uses two main types of insulating materials:

To choose the most durable and high-quality material, you will need to familiarize yourself in more detail with the characteristics of each of them.

Polystyrene is a popular insulating material, which is distinguished by the presence of a gas-filled structure. This polymer is made up of granules that have been obtained from petroleum refining. El proceso de producción del material implica el uso de un método de expansión y sinterización adicional de todos los gránulos que se llenan con masas de aire. Por lo tanto, su volumen aumenta 50 veces.

Si comparamos la espuma de poliestireno expandido con otro aislamiento popular: la lana mineral, podemos notar el menor peso del primer material, su resistencia mecánica y el coeficiente mínimo de conductividad térmica.

Debido a su bajo peso, la capa de aislamiento proporciona la forma más sencilla posible de fijación a superficies verticales y también elimina la tensión adicional en todas las estructuras de soporte.

Contact us and we will resolve any questions you have about our

SATE CARAVISTA products.

Calle Palauet, 131

Catalunya – Lleida – 25001

Email: info@starmodul.com

Tel: +34 973 22 81 64

Móvil: +34 683 44 26 08

¿Necesitas ayuda?